Future Development of Cloud Computing under Intelligent Manufacturing Trend

Author/Liu Ruilong [Issue Date: 2016/6/6

Leaderette: The author was invited to give an address named 'Future development of cloud computing under intelligent manufacturing trend' at the China Cloud Computing Conference held on May 19. He received a warm reception to his speech because of the wonderful contents. Therefore, the editorial department specially invites this contributor to share it with more readers.

Perface

At noon on March 15, 2016, the nine-dan chess player from South Korea, Li shishi ranking fourth in the world played chess with Google's AI program AlphaGo. After five days of fierce battle, AlphaGo finally won this competition with the total score 4:1 thereby qualifying as the world's fourth best player. AI (Artificial Intelligence) is a growing trend in recent years. Apart from board games, intelligent manufacturing already makes extensive use of artificial intelligence.

Significant Challenges that the Manufacturing Industry is Facing

To answer why the manufacturing industry needs to be intelligent, here we must mention five key challenges the global manufacturing industry is facing at the moment.

1. Increased demand for personal products

In the era of multi-screens in one cloud, people have many devices like notebooks calculators, tablet computers and often more than one smart phone, and each product has different dimensions. This requires a fast adjustment with highly flexibility production lines.

2. Significantly shortened product life cycles

The mobile phone is the most typical example. For current smart phones, the average life cycle, in general, is 1.6 years; even some manufactures, Samsung for example, launch a new mobile phone every three months on average to meet the demand for new features and innovative ideas of the target market.

3. Introduction of new generation interaction models between humans and computers

In the past, we only input data into mobile phones to do a unidirectional query. Now even when watching TV, we can vote or otherwise participate in the draw along with the guests on site by scanning QR codes. In a manufacturing plant, through the import of information technology, operators are upgraded to controllers, and the output is upgraded as well.

4. Transform of social structure

There is a growing labor shortage coming in the wake of an increasingly elderly population and a decline in the young working population.

5. Issue of sustainable development

Production processes with high pollution are being gradually phased out, and the carbon footprint, highly efficient energy use is the challenge the manufacturing industry is facing.

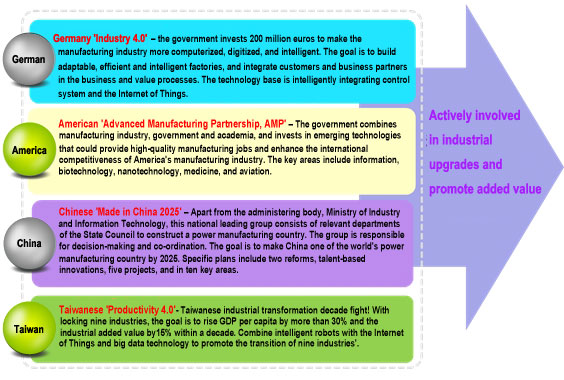

These five challenges shows that many of the old modes of production in the manufacturing industry have been inconsistent with global trends and their cost is too high. It's time to upgrade. Intelligent manufacturing is vital for a country to improve overall manufacturing output and international competitiveness, therefore in recent years all the countries actively promote the construction of intelligent manufacturing, production and sales systems to make correct predictions about and timely responses to market demands. Here are some examples, Germany 'Industry 4.0', the United States' 're-industrialization policy', Japan's 'future factory of human coexistence', Korean 'next generation of intelligent factory', and Chinese ' Made in China 2025'. Secondly, in order to cope with the inevitable trend of decline in the employee population, the advanced countries driven the development of digital manufacturing and intelligent manufacturing integrating reality and network. It's an important means of reversing the population crisis.

Material Source: provided by Lingan Computer Co., May, 2016

Intelligent manufacturing, cloud computing and big data

The ultimate goal of promoting intelligent manufacturing is to fully integrate IT (Information Systems Information Technology) and OT (operating techniques Operational Technology) through the Internet of Things and big data technology. It's a circular improving process without end. The improvements on the IT side include keeping abreast of producing status and delivery date, getting results of optimizing productivity and quality, and improving enterprises' operational efficiency. The improvements on the OT side include faster reflection of real-time status, optimization of the manufacturing process, and arranging work priorities appropriately to reduce risks.

Both Industry 4.0 and intelligent manufacturing can drive the value of the entire ecosystem with tremendous efficiency. Horizontal integration crosses industries and value chains, and involves software tools industry, machinery equipment industry, system integration industry, production manufacturing industry, and even channel industry that provides maintenance services. In order to achieve requirements of intelligent manufacturing, enterprises even need to do transparent vertical integration by an adjustable system with high elasticity.

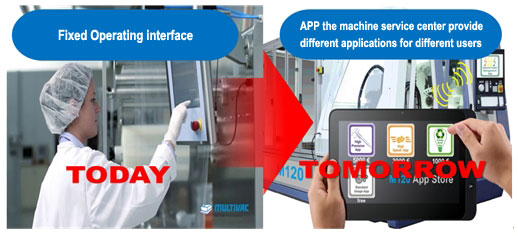

There are many intelligent manufacturing practices different from those of the traditional manufacturing process. The purpose is to solve the previously mentioned five challenges. Take human-computer interaction for example, now in most plants operator interfaces is still fixed to machines, and therefore workers even need to wear clean clothes when entering production lines to regulate the management and the job. This does not meet the principles of human body health. Gradually, some manufacturers have adopted intelligent manufacturing to reconstruct their systems. In this way, the administrators can control processes in the service center with applications provided by machine service center, which indirectly improve the efficiency of the production line. (See Figure II)

Material Source: DFKI GmbH

The solution to the problem of diversity of production lines is to concentrate technical assistant in the control room. Unmanned factories appeared in 1986, however, if there are exceptions during production, operators still need to run to the production line to deal with the exception. Now by the use of intelligent manufacturing, all operators, perhaps now called administrators, can do the operations and control the processes primarially in the service center or control room, without enduring inconvenience of going to the toilet and breathing exhaust gas that may be harmful to humans.

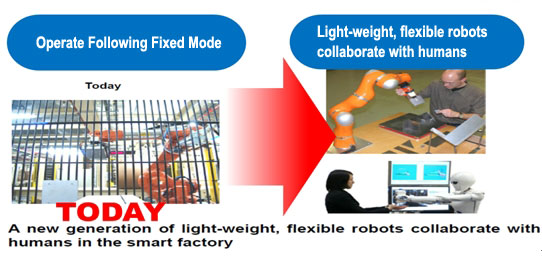

In order to change social structure, the intelligent manufacturing plants import high elasticity robots to assistant employees. Future robots will operate following a fixed mode and through the import of artificial intelligence cooperate with the senior staffs to co-product. These robots can do some more sophisticated productions in which eyesight is necessary. (See Figure III)

Material Source: DFKI GmbH

Production facilities in intelligent factories are good data sources, because all of them would produce data, from sources such as sensors, machines, testing machines, detection, and access control. For example, in a machine worth 10 million, there are 400 sensors, and therefore 400 pieces of data per second per machine will be produced. Then, the amount of data per hour produced by a plant would reach 1,440 pieces (400/second/machine * 10 machine * 60 second * 60 minute = 1,440). Such a large amount of data would be a big fortune if is fully made use of. The big data of the intelligent factory would be applied to detection, diagnosis, controlling, forecasting, etc, and be present with visual interface to make them easy to understand and for TA (technical assistant) to operate.

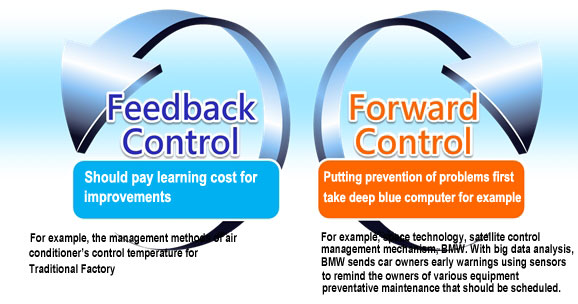

What's the connection between intelligent manufacturing and cloud computing? Some people may think that intelligent manufacturing only needs investment, and it can be achieved as long as you have enough funds to heavily invest in automated production equipments. However, this is not true. The key point of success is to change management methods. The mode of process management in the past was Feedback Control which is still used by most factories today. When there is something wrong in the production line, too high or too low temperature for instance, the operators quickly make equipment adjustments. This means that you should pay learning cost for improvements. But intelligent manufacturing adapts Forward Control which emphasizes the prevention of problems first. Intelligent manufacturing factories reduce the probability of damage by preventing mistakes through big data analysis. (See Figure IV)

Material Source: provided by Lingan Computer Co., May, 2016

Conclusions

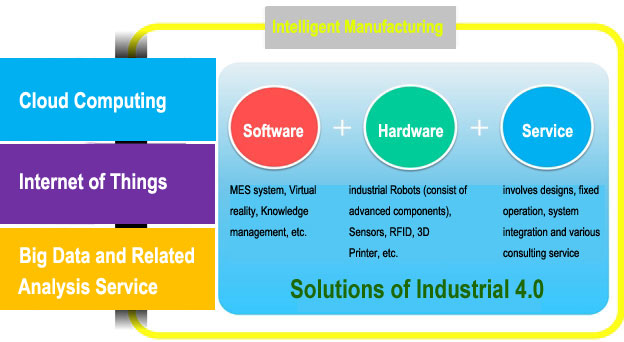

Now is a good time to develop intelligent manufacturing. Countries, such as German and America, are talking about Industry 4.0. 'Solution to Industry 4.0' that consists of many things need in the manufacturing industry, including software (including MES (Manufacturing Execution System), VR (virtual reality), knowledge management), hardware (including industrial robots, sensors, RFID, 3D printers) and related designs, maintenance, systems integration and various consultant information services. If the three value chains - "cloud computing", "Internet of things" and "big data and analysis services"- are added to support the architecture of intelligent manufacturing, 'solution to industry 4.0' will be more completed. (See Figure V)

Material Source: provided by Lingan Computer Co., May, 2016

Previously in order to improve the factory's output, we just need to spend money buying equipments and employing good workers to work together. However, in the era of intelligent manufacturing, it will not work to only rely on money and the number of workers, and intelligence is also needed. The most important thing is that we should have the knowledge of cloud computing, the internet of things, intelligent robots and big data analysis. In addition, we also need to improve employee's abilities through relevant technical support, and then turn them from simple production operators to controller and managers (upgrade of manpower qualities).

More valuable, finding employees with cross-field knowledge, intelligent manufacturing companies could find innovative application modes with commercial value. For example, "DiDi Travel" (similar to Chinese Uber) is an example of innovative applications. It's an investment project of $1 billion announced by Apple, Inc. on May 13 of this year.

The biggest challenge for intelligent factories is 'integration'. The key points are how to optimize the adjustment of machines, sensors, and sensing components of each factory according to different production process, so that the output data meets valid integration. Meanwhile, an important factor for intelligent factories that add analysis service in the process of an integration process to improve outputs is challenging the wisdom of the current plant development. Faced with the trend of stronger and stronger competition in the global market, manufacturing industry and governments have to follow this path. By making the correct moves and investing for the long haul, it will be a good transition. Therefore, It's a path to success for manufacturing industry that make good use of the professional knowledge and the ability of systematically integrating industries.